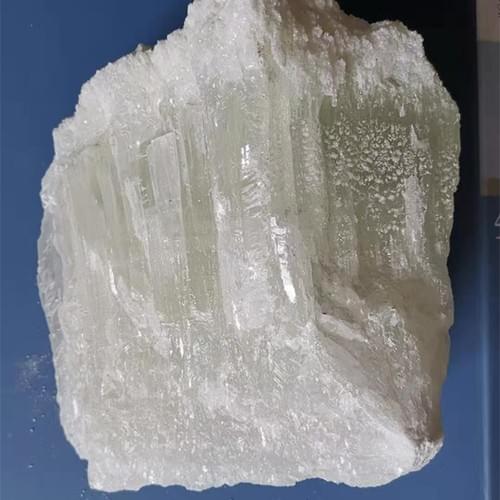

Fused magnesia

Application of Fused magnesite:

1. Metallurgical refractory materials: Used to make high-purity fused magnesite, gunning materials, ramming materials and other auxiliary refractory materials, as well as special refractory bricks such as pouring nozzle bricks, magnesia bricks, and magnesia-chrome bricks. It can also be used for the refractory furnace linings of vacuum and non-vacuum induction furnaces and electric arc furnaces. It is an ideal raw material for making magnesia crucibles, ladles and various high-temperature tube.

2. Building materials and chemical industry: Used to make various magnesia bricks, magnesia-alumina bricks, ramming materials, patching materials, etc., and is one of the important raw materials for refractory materials. Fused magnesite with more impurities is used for paving the bottom of steel-making converters.

3. Electrical and ceramic fields: It has excellent alkali resistance and electrical insulation at high temperatures and is widely used as a high-temperature heat-resistant material. In the ceramic field, it is used as a raw material for translucent ceramic crucibles, substrates, etc. When used as a ceramic substrate, its thermal conductivity is twice that of alumina, and the loss of electrolytic products is only 1/10 of that of alumina.

4. Other applications: Fused magnesite is also widely used in metallurgy, chemical industry, national defense, scientific research, aerospace, household electrical appliance components and other fields, and has good high-temperature mechanical strength and corrosion resistance performance.

5. Capacity: 25mts/Day; 9000mts/year